|

|

|

|

| Page View 29347 |

| Product Information : |

|

|

| Product Name: |

|

DAIYAC COLLET CHUCK & GUIDE BUSH SPINDLEs for Micro-machining |

|

| Product Category: |

|

เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

|

| Product Sub-Category: |

|

DAIYAC Collet Chuck & GUIDE BUSH

|

| Brand: |

|

DAIYAC COLLET CHUCK & GUIDE BUSH |

| Product Type : |

|

เครื่องมือ, เครื่องจักรและอุปกรณ์

|

| Short Description : |

|

DAIYAC COLLET CHUCK & GUIDE BUSH SPINDLEs for Micro-machining

High-speed, High-precision Spindle LA-600 for Micro-Machining |

| |

|

|

| |

LA-600

High-speed, High-precision Spindle LA-600 for Micro-Machining

|

The high-speed, high-precision spindle LA-600 is a high-speed spindle unit fine-tuned to meet micro-machining needs. Rotating at the high speed of 60,000 revolutions per minute, the spindle demonstrates outstanding cutting performance and finishing accuracy in end-mill or drill machining.

|

|

| Maximum revolution speed : 60,000min-1 (rpm) |

Spindle accuracy : 1μm or better |

| A combination of air cooling and ceramic bearing realizes the speeds of 10,000 to 60,000min-1 (rpm) . |

The spindle accuracy is better than 1μm. Even the dynamic run-out accuracy is within the control. |

Compact size and high-rigidity stainless steel body

| The spindle body is as short as 149mm. The motor and spindle exteriors are all stainless steel (SUS420J2). The spindle clamp, which is hardened and grinder-finished, are of high-rigidity specifications. |

|

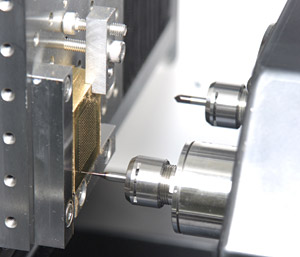

Photograph of processing by BISSIAH MD20

High power of max.370W output and flat torque

| A flat torque characteristic is displayed over the whole speed range of 10,000 to 60,000 min-1 (rpm). The brushless motor is a highly reliable and durable type. The maximum output is as high as 370W. |

| Output and Torque Curves |

|

Principal Uses

| * |

Use as tooling for end-mill machining or grinding with an end-mill or grinding wheel attached to the spindle end on a comb-type lathe. |

| * |

Use for small-bore hole finishing (bore polishing) in a lathe operation. |

| * |

Use for deburring, drilling (by a drill) or slitting by a metal saw with this spindle attached to a dedicated machine. |

| * |

Use for deburring or polishing with this spindle attached to the end of a robot arm. |

LA-600A

High-speed, High-precision Attachment Spindle for Micro-machining

| LA-600A, attached to your existing NC milling machine or machining center, will realize high-speed machining. At a high speed of 60,000min-1(rpm) , this spindle displays superior cutting performance and finishing in small-diameter end-mill cutting or drilling. |

|

|

Maximum revolution speed : 60,000min-1 (rpm)

Spindle accuracy : 1μm or better

High power of max. 370W output and flat torque characteristic

A combination of brushless motor and ceramic bearing

The spindle is driven by a direct-drive brushless motor. Without any speed increase with gears or the like, this spindle causes little heating or vibration, which contributes to producing finely finished surface.

esponsive to various attaching tapers

The spindle can be fitted to various tapers of BT, HSK and other shanks.

Product Specifications

| Revolution speed |

10,000 to 60,000min-1 (rpm) |

| Maximum output |

370w |

| Spindle accuracy |

1μm or better |

| Cooling air supply |

0.2 to 0.5MPa

Clean dry air

4mm tube dia |

Collet chuck

(option) |

Daiya's CCER11-SR used (AA class or above recommended)

Holding diameter : 0.5 to 6.0 mm (Chuck nut wrench included) |

●BT50-type Diameter

Installation photograph of machining

Data on grooving in hardened die steel

| Comparison of machining data between the conventional general-purpose machining center and the LA-600A attached to a general-purpose machining center. |

| Material |

SKD11 (HRc61) |

| Tool |

Carbide solid molded end mill (non-coated) |

| Groove length |

143mm |

| |

LA-600 |

General-purpose machining center |

Revolution speed

N [min-1] |

50,000 |

5,000 |

Feed rate

F [mm/min] |

250 |

15 |

| Depth of cut (Z direction) [mm/min] |

0.1 |

0.05 |

| Relative roughness of surface |

○(Visual) |

○(Visual) |

| Tool life |

○ |

x |

| Grooving time [min] |

3min 40sec |

40min or more |

|

|

Control Unit

This is a compact-size, highly-functional control unit for the LA series.

Highly-functional

|

|

| Revolution speed display, alarm display, external control function. |

Protective functions

|

| Cooling air supply monitor, overload monitor, cord break monitor, revolution monitor |

External control input/output

|

|

(Remove the center cover of the front panel, and there are input/output terminals.)

Power ON/OFF, Forward/Reverse revolution, RPM UP/DOWN, RPM/Current monitor, Alarm output

|

Names of Parts

| 1 |

Main power switch |

| 2 |

Rotation switch |

| 3 |

Start switch |

| 4 |

Speed Down switch |

| 5 |

Speed Up switch |

| 6 |

Revolution speed display |

| 7 |

Air Out |

| 8 |

Air In |

| 9 |

External input terminal |

| 10 |

Serial connector (RS232C) |

| 11 |

Motor connector |

| 12 |

Power main switch |

| 13 |

AC IN power socket |

|

|

Product Specifications

| Power supply |

100VAC, 50/60Hz

220VAC, 50/60Hz (option)

240VAC, 50/60Hz (option) |

| Air supply |

0.2 to 0.5MPa

Clean dry air

(Air supply being monitored by controller)

4 mm diam. x 5 m tube included |

| Rated power |

123w |

| Mass |

2.4kg |

| Dimensions |

200(W) x 220(D) x 42(H) mm |

Custom-made

| Daiya Seiki is designing and manufacturing a variety of high-precision and high-speed spindles for use in production equipment and dedicated machinery or as OEM products. |

|

| High-speed spindles for dedicated machinery |

|

| Spindles for pneumatic static-pressure bearings (air bearings) |

|

| |

|

|

|

|

|

|

|