Test Bar Test Arbor เทสบาร์ ISO Test Bar Test Bar HSK

BBT Test Bar เทสอาร์เบอร์ รุ่น BT Test Arbor BBT40 test bar Accuracy:?0.003mm BBT30 BBT40 Test Bar BT BT30 BT40 BT50 ISO Test Bar ISO20 ISO25 ISO30 Test Bar HSK HSK25E HSK32E HSK32A HSK40E HSK40A/E HSK50E HSK50A HSK63A HSK63F HSK100A

BBT Test Bar เทสอาร์เบอร์ รุ่น BT Test Arbor BBT40 test bar Accuracy:?0.003mm BBT30 BBT40 Test Bar BT BT30 BT40 BT50 ISO Test Bar ISO20 ISO25 ISO30 Test Bar HSK HSK25E HSK32E HSK32A HSK40E HSK40A/E HSK50E HSK50A HSK63A HSK63F HSK100A

Last Update : 27/05/2024 08:34:20

POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center

ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center

ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center

Last Update : 14/05/2024 11:44:31

จำหน่ายสินค้าของทาง Arobotech AUTO REST

จำหน่ายและนำเข้าสินค้าของทาง Arobotech AUTO REST AROBOTECH STEADY REST สนใจติดต่อได้ที่คุณภูรินทร์ 098-4288648 LINE ID : 0984288648

จำหน่ายและนำเข้าสินค้าของทาง Arobotech AUTO REST AROBOTECH STEADY REST สนใจติดต่อได้ที่คุณภูรินทร์ 098-4288648 LINE ID : 0984288648

Last Update : 18/03/2024 17:27:54

Lathe Turret Alignment Bars

Lathe Turret Alignment Bars สนใจสินค้าสอมถาม [email protected];[email protected] : Mobile : K.ภูรินทร์ 098-4288648 Line ID : 0984288648

Lathe Turret Alignment Bars สนใจสินค้าสอมถาม [email protected];[email protected] : Mobile : K.ภูรินทร์ 098-4288648 Line ID : 0984288648

Last Update : 18/03/2024 14:34:51

A2 Flanged Lathe Spindle Runout Test Bars

A2 Flanged Lathe Spindle Runout Test Bars สนใจสอบถาม สินค้าติดต่อ [email protected];[email protected] : Mobile : K.ภูรินทร์ 098-4288648 Line ID : 0984288648

A2 Flanged Lathe Spindle Runout Test Bars สนใจสอบถาม สินค้าติดต่อ [email protected];[email protected] : Mobile : K.ภูรินทร์ 098-4288648 Line ID : 0984288648

Last Update : 18/03/2024 14:30:04

Runout Arbors for lathe Centers

TAC Rockford runout arbors for lathe centers are manufactured using hardened gauge-quality steel, and include a certificate of accuracy.

TAC Rockford runout arbors for lathe centers are manufactured using hardened gauge-quality steel, and include a certificate of accuracy.

Last Update : 18/03/2024 14:28:05

HSK Tool Changer Alignment Gauges

HSK Tool Changer Alignment Gauges HSK-A 25, 32, 40, 50, 63, 80, 100, 125

HSK Tool Changer Alignment Gauges HSK-A 25, 32, 40, 50, 63, 80, 100, 125

Last Update : 13/03/2024 15:09:44

ATC Tool Changer Alignment Gauge Kit

ATC Alignment tool ATC Alignment Tool ATC Arm Aligning Equipment BT30/40/50 ATC ALIGNMENT TOOL SET Automatic Tool Changer alignment tool

ATC Alignment tool ATC Alignment Tool ATC Arm Aligning Equipment BT30/40/50 ATC ALIGNMENT TOOL SET Automatic Tool Changer alignment tool

Last Update : 13/03/2024 14:59:04

MicroCentric SPECIAL TURNKEY WORKHOLDING SYSTEMS

MicroCentric SPECIAL TURNKEY WORKHOLDING SYSTEMS สนใจสินค้าติดต่อบริษัทสำหรับงาน TURNKEY

MicroCentric SPECIAL TURNKEY WORKHOLDING SYSTEMS สนใจสินค้าติดต่อบริษัทสำหรับงาน TURNKEY

Last Update : 24/02/2024 08:08:54

Universal Punch เครื่องวัดค่าความร่วมศูนย์ สำหรับชิ้นงานกลม Concentricity Gage

สำหรับชิ้นงานกลม Concentricity Gage Universal Punch เครื่องวัดค่าความร่วมศูนย์ สำหรับชิ้นงานกลม Concentricity Gage

สำหรับชิ้นงานกลม Concentricity Gage Universal Punch เครื่องวัดค่าความร่วมศูนย์ สำหรับชิ้นงานกลม Concentricity Gage

Last Update : 24/02/2024 08:05:47

MicroCentric Air Chuck

Quick Change Collet Chucks Precision Air Chucks Precision Power Chucks Conventional Collet Chucks Diaphragm Chucks KSF Power Chucks SPECIAL TURNKEY WORKHOLDING SYSTEMS สนใจสินค้าสอบถามที่เบอร์ 0984288648 คุณภูรินทร์

Quick Change Collet Chucks Precision Air Chucks Precision Power Chucks Conventional Collet Chucks Diaphragm Chucks KSF Power Chucks SPECIAL TURNKEY WORKHOLDING SYSTEMS สนใจสินค้าสอบถามที่เบอร์ 0984288648 คุณภูรินทร์

Last Update : 24/02/2024 08:04:43

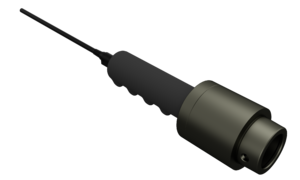

เครื่องวัดแรงดึง ForceCheck for Spindel Machine

เครื่องวัดแรงดึง DRAWBAR CLAMPING FORCE GAGE Spindle Drawbar Force Gauge Drawbar Gauge Spindle Clamping Force Force Check KM6350 KM10080 Spindle Draw Bar force gauge testing CNC DrawBar Gauge Tool Clamping Force Clamp Force Meter Drawbar Force Gauge

เครื่องวัดแรงดึง DRAWBAR CLAMPING FORCE GAGE Spindle Drawbar Force Gauge Drawbar Gauge Spindle Clamping Force Force Check KM6350 KM10080 Spindle Draw Bar force gauge testing CNC DrawBar Gauge Tool Clamping Force Clamp Force Meter Drawbar Force Gauge

Last Update : 12/12/2023 13:04:35

จำหน่าย microcentric

จำหน่าย microcentric

จำหน่าย microcentric

Last Update : 26/09/2023 16:55:12

YHB Disk-type Oil Skimmer

YHB Disk-type Oil Skimmer Disc Type Oil Skimmer Belt Type Oil Skimmer, Disc type Disc Type Oil Skimmer Oil skimmer แบบจาน ใช้แยกน้ำมันหล่อลื่น (Tramp oil) ที่ลอยอยู่บนน้ำมันหล่อเย็น เหมาะที่จะติดตั้งบนถังน้ำมันหล่อเย็นของเครื่อง CNC Disc Oil Skimmers, Oil Skimmers, Disc Type Oil Skimmers Oil Skimmer เครื่องดูดคราบน้ำมันแบบเคลื่อนที่ ใช้งานง่าย สะดวก

YHB Disk-type Oil Skimmer Disc Type Oil Skimmer Belt Type Oil Skimmer, Disc type Disc Type Oil Skimmer Oil skimmer แบบจาน ใช้แยกน้ำมันหล่อลื่น (Tramp oil) ที่ลอยอยู่บนน้ำมันหล่อเย็น เหมาะที่จะติดตั้งบนถังน้ำมันหล่อเย็นของเครื่อง CNC Disc Oil Skimmers, Oil Skimmers, Disc Type Oil Skimmers Oil Skimmer เครื่องดูดคราบน้ำมันแบบเคลื่อนที่ ใช้งานง่าย สะดวก

Last Update : 08/09/2023 07:28:13

Tools presetter เครื่องวัดระยะหัวกัด CNC มิลลิ่ง จากประเทศเยอรมนี

Tools presetter เครื่องวัดระยะหัวกัด CNC มิลลิ่ง เครื่องเซ็ตอุปกรณ์สำหรับเครื่องจักร KELCH Tool presetting จากประเทศเยอรมนี

Tools presetter เครื่องวัดระยะหัวกัด CNC มิลลิ่ง เครื่องเซ็ตอุปกรณ์สำหรับเครื่องจักร KELCH Tool presetting จากประเทศเยอรมนี

Last Update : 25/07/2023 13:10:13

KELCH Safecontrol 4.0 Force Check

KELCH Safecontrol 4.0 Force Check for spindle force BT30 BT40 BT50 HSK25 HSK32 HSK40 HSK50 HSK63 HSK100

KELCH Safecontrol 4.0 Force Check for spindle force BT30 BT40 BT50 HSK25 HSK32 HSK40 HSK50 HSK63 HSK100

Last Update : 24/07/2023 15:36:12

ForceCheck - TAC Rockford

ForceCheck - TAC Rockford ForceCheck HSK Taper Drawbar Force Gauges For measuring drawbar retention force on HSK (Hollow-Shank Taper) standard spindles

ForceCheck - TAC Rockford ForceCheck HSK Taper Drawbar Force Gauges For measuring drawbar retention force on HSK (Hollow-Shank Taper) standard spindles

Last Update : 23/07/2023 08:40:34

Polygon Solutions Rotary Broach Tools T-40 Torx GO and NOGO Gage Set

Rotary Broaches Rotary Broach Tool Holders Go & NoGo Gages Torx Rotary Broaches Rotary Broach Tool Holders Go & NoGo Gages Hexagon (Hex) Go/NoGo Gages Square Go/No-Go Gauges Hexalobular Go/NoGo Gages T-40 Torx GO and NOGO Gage Set

Rotary Broaches Rotary Broach Tool Holders Go & NoGo Gages Torx Rotary Broaches Rotary Broach Tool Holders Go & NoGo Gages Hexagon (Hex) Go/NoGo Gages Square Go/No-Go Gauges Hexalobular Go/NoGo Gages T-40 Torx GO and NOGO Gage Set

Last Update : 21/07/2023 17:35:40

Branson เครื่องเชื่อมสายไฟฟ้าสำหรับโรงงานจากประเทศอเมริกา

Branson เครื่องเชื่อมสายไฟฟ้าสำหรับโรงงานจากประเทศอเมริกา

Branson เครื่องเชื่อมสายไฟฟ้าสำหรับโรงงานจากประเทศอเมริกา

Last Update : 19/07/2023 15:44:04

Branson เครื่องล้างอุลตร้าโซนิกจากประเทศสหรัฐ USA คุณภาพสูง

Branson | Welding & Cleaning Equipment เครื่องทำความสะอาดอัลตราโซนิก Ultrasonic ในงานโรงงานอุตสาหกรรม Ultrasonic Cleaner คืออุปกรณ์ทำความสะอาดที่ใช้คลื่นความถี่สูงอัลตร้าซาวด์ บริษัทขายเครื่องล้างอัลตร้าโซนิค. Ultrasonic Cleaner ถูกใช้ในอุตสาหกรรม Ultrasonic Cleaner (เครื่องล้างความถี่สูง)

Branson | Welding & Cleaning Equipment เครื่องทำความสะอาดอัลตราโซนิก Ultrasonic ในงานโรงงานอุตสาหกรรม Ultrasonic Cleaner คืออุปกรณ์ทำความสะอาดที่ใช้คลื่นความถี่สูงอัลตร้าซาวด์ บริษัทขายเครื่องล้างอัลตร้าโซนิค. Ultrasonic Cleaner ถูกใช้ในอุตสาหกรรม Ultrasonic Cleaner (เครื่องล้างความถี่สูง)

Last Update : 19/07/2023 15:33:24

Concentricity Gages

Brand : Concentricity Gages

Concentricity Gage บริษัท เมคคาทรอนิกส์ แมชชีน ทูลส์ จำกัด UNIVERSAL PUNCH Concentricity Gages A-10 B-10 B-20 B-40 E-10 E-20 E-40 F-10 F-20 G1-10 G1-20 G1-40 G2-10 G2-20 G2-40 H-10 H-20 H-40 HL-10 HL-20 HL-40 JLS-10 JLP-10 J-10 J-20 J-40 K1-10 K1-20 K1-40 K2-10 K2-20 K2-40 KK1-10 KK1-20 KK1-40 KK2-10 KK2-20 KK2-40 LG-10 LGM-10 Concentricity Gages

Concentricity Gage บริษัท เมคคาทรอนิกส์ แมชชีน ทูลส์ จำกัด UNIVERSAL PUNCH Concentricity Gages A-10 B-10 B-20 B-40 E-10 E-20 E-40 F-10 F-20 G1-10 G1-20 G1-40 G2-10 G2-20 G2-40 H-10 H-20 H-40 HL-10 HL-20 HL-40 JLS-10 JLP-10 J-10 J-20 J-40 K1-10 K1-20 K1-40 K2-10 K2-20 K2-40 KK1-10 KK1-20 KK1-40 KK2-10 KK2-20 KK2-40 LG-10 LGM-10 Concentricity Gages

Last Update : 17:13:07 29/05/2024

DACELL Loadcell Torque sensor

Brand : DACELL

Model : DACELL Loadcell Torque sensor

DACELL Loadcell Torque sensor DACELL Loadcell Torque sensor

Model : DACELL Loadcell Torque sensor

DACELL Loadcell Torque sensor DACELL Loadcell Torque sensor

Last Update : 17:12:40 29/05/2024

SMW AUTOBLOK Product Overview

Brand : SMW AUTOBLOK

Model : SMW AUTOBLOK Product Overview

SMW AUTOBLOK Product Overview

Model : SMW AUTOBLOK Product Overview

SMW AUTOBLOK Product Overview

Last Update : 17:12:20 29/05/2024

KHAN CHUCK

Brand : KHAN CHUCK

Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table Special Chuck

Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks Special Purpose Power Chucks NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table NC rotary table Special Chuck

Last Update : 17:11:31 29/05/2024

FIMEC AUTOMATIC TOOL CHANGE SPINDLE MOTORS

Brand : FIMEC

Model : ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350

ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350

Model : ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350

ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350 ES915 ES929 ES939 ES988 ES325 ES326 ES327 ES330 ES350

Last Update : 17:10:55 29/05/2024

MicroCentric Air Cylinder Models

Brand : MicroCentric Air Cylinder Models

MicroCentric Air Cylinder Models

MicroCentric Air Cylinder Models

Last Update : 17:09:44 29/05/2024

Quick Change Collet Chucks

Brand : MicroCentric Quick Change Collet Chucks

MicroCentric Quick Change Collet Chucks

MicroCentric Quick Change Collet Chucks

Last Update : 17:02:37 29/05/2024

Precision Power Chucks

Brand : MicroCentric

MicroCentric Precision Power Chucks

MicroCentric Precision Power Chucks

Last Update : 16:54:13 29/05/2024

จำหน่ายสินค้า MicroCentric

Brand : MicroCentric

จำหน่ายสินค้า MicroCentric Precision Air Chuck Models สนใจติดต่อคุณภูรินทร์ 0984288648

จำหน่ายสินค้า MicroCentric Precision Air Chuck Models สนใจติดต่อคุณภูรินทร์ 0984288648

Last Update : 16:49:18 29/05/2024

ตัวแทนจำหน่าย AROBOTECH AUTO REST

Brand : ตัวแทนจำหน่าย AROBOTECH AUTO REST

AROBOTECH Grinding AUTO REST Precision Grinding with .001mm Repeatability สนใจหรือสอบถามได้ที่คุณภูรินทร์ 0984288648

AROBOTECH Grinding AUTO REST Precision Grinding with .001mm Repeatability สนใจหรือสอบถามได้ที่คุณภูรินทร์ 0984288648

Last Update : 16:30:48 29/05/2024

ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2

Brand : OTT-JAKOB

ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center

ตัวแทนจำหน่ายสินค้า OTT-JAKOB Power-Check 2 OTT-JAKOB POWER-CHECK เครื่องมือวัดแรงดึงของเครื่องจักร CNC Machining Center

Last Update : 11:43:17 14/05/2024

Universal Punch เครื่องวัดค่าความร่วมศูนย์

Brand : เครื่องวัดค่าความร่วมศูนย์สำหรับชิ้นงานกลม Concentricity Gage

Universal Punch เครื่องวัดค่าความร่วมศูนย์สำหรับชิ้นงานกลม Concentricity Gage A-10 Universal Punch Concentricity Gage B-40 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage G1-10 Universal Punch Concentricity Gage E-10 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage HL-40 Universal Punch Concentricity Gag J-10 Universal Punch Concentricity Gage H-20 Universal Punch Concentricity Gage H-10 Universal Punch Concentricity Gage G2-20 Universal Punch Concentricity Gage B-20 Universal Punch Concentricity Gage H-40 Universal Punch Concentricity Gage H-20 Universal Punch Concentricity Gage H-10 Universal Punch Concentricity Gage G2-40 Universal Punch Concentricity Gage G2-20 Universal Punch Concentricity Gage G2-10 Universal Punch Concentricity Gage G1-40 Universal Punch Concentricity Gage G1-20 Universal Punch Concentricity Gage G1-10 Universal Punch Concentricity Gage F-20 Universal Punch Concentricity Gage F-10 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage E-20 Universal Punch Concentricity Gage E-10 Universal Punch Concentricity Gage B-40 Universal Punch Concentricity Gage B-20 Universal Punch Concentricity Gage B-10 Universal Punch Concentricity Gage A-10 Universal Punch Concentricity Gage KK1-40 Universal Punch Concentricity Gage KK1-20 Universal Punch Concentricity Gage KK1-10 Universal Punch Concentricity Gage K2-40 Universal Punch Concentricity Gage K2-20 Universal Punch Concentricity Gage K2-10 Universal Punch Concentricity Gage K1-40 Universal Punch Concentricity Gage K1-20 Universal Punch Concentricity Gage K1-10 Universal Punch Concentricity Gage JSLP-10C Universal Punch Concentricity Gage JSLP-10 Universal Punch Concentricity Gage JLP-10 Universal Punch Concentricity Gage J-40 Universal Punch Concentricity Gage J-20 Universal Punch Concentricity Gage J-10 Universal Punch Concentricity Gage HL-40 Universal Punch Concentricity Gage HL-20 Universal Punch Concentricity Gage HL-10 Universal Punch Concentricity Gage LG-20 Universal Punch Concentricity Gage LG-10 Universal Punch Concentricity Gage KK2-40 Universal Punch Concentricity Gage KK2-20 Universal Punch Concentricity Gage KK2-10 Universal Punch Concentricity Gage

Universal Punch เครื่องวัดค่าความร่วมศูนย์สำหรับชิ้นงานกลม Concentricity Gage A-10 Universal Punch Concentricity Gage B-40 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage G1-10 Universal Punch Concentricity Gage E-10 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage HL-40 Universal Punch Concentricity Gag J-10 Universal Punch Concentricity Gage H-20 Universal Punch Concentricity Gage H-10 Universal Punch Concentricity Gage G2-20 Universal Punch Concentricity Gage B-20 Universal Punch Concentricity Gage H-40 Universal Punch Concentricity Gage H-20 Universal Punch Concentricity Gage H-10 Universal Punch Concentricity Gage G2-40 Universal Punch Concentricity Gage G2-20 Universal Punch Concentricity Gage G2-10 Universal Punch Concentricity Gage G1-40 Universal Punch Concentricity Gage G1-20 Universal Punch Concentricity Gage G1-10 Universal Punch Concentricity Gage F-20 Universal Punch Concentricity Gage F-10 Universal Punch Concentricity Gage E-40 Universal Punch Concentricity Gage E-20 Universal Punch Concentricity Gage E-10 Universal Punch Concentricity Gage B-40 Universal Punch Concentricity Gage B-20 Universal Punch Concentricity Gage B-10 Universal Punch Concentricity Gage A-10 Universal Punch Concentricity Gage KK1-40 Universal Punch Concentricity Gage KK1-20 Universal Punch Concentricity Gage KK1-10 Universal Punch Concentricity Gage K2-40 Universal Punch Concentricity Gage K2-20 Universal Punch Concentricity Gage K2-10 Universal Punch Concentricity Gage K1-40 Universal Punch Concentricity Gage K1-20 Universal Punch Concentricity Gage K1-10 Universal Punch Concentricity Gage JSLP-10C Universal Punch Concentricity Gage JSLP-10 Universal Punch Concentricity Gage JLP-10 Universal Punch Concentricity Gage J-40 Universal Punch Concentricity Gage J-20 Universal Punch Concentricity Gage J-10 Universal Punch Concentricity Gage HL-40 Universal Punch Concentricity Gage HL-20 Universal Punch Concentricity Gage HL-10 Universal Punch Concentricity Gage LG-20 Universal Punch Concentricity Gage LG-10 Universal Punch Concentricity Gage KK2-40 Universal Punch Concentricity Gage KK2-20 Universal Punch Concentricity Gage KK2-10 Universal Punch Concentricity Gage

Last Update : 17:55:32 23/02/2024

จำหน่าย Mechanical rotary tables

Brand : Mechanical rotary tables

จำหน่าย Mechanical rotary tables สนใจสินค้าสอบถามที่คุณภูรินทร์ 0984288648

จำหน่าย Mechanical rotary tables สนใจสินค้าสอบถามที่คุณภูรินทร์ 0984288648

Last Update : 09:15:13 18/12/2023

Pneumatic rotary tables กระบอกลมแบบหมุนล็อคตำแหน่ง

Brand : Pneumatic rotary tables

Pneumatic rotary tables กระบอกลมแบบหมุนล็อคตำแหน่งโดยใช้ลม G.P.A. Italiana pneumatic rotary indexing tables are available in two versions: TAR 270 and TAR 160 ขนาดโต๊ะหมุนมีสองแบบ 160 mm 270 mm

Pneumatic rotary tables กระบอกลมแบบหมุนล็อคตำแหน่งโดยใช้ลม G.P.A. Italiana pneumatic rotary indexing tables are available in two versions: TAR 270 and TAR 160 ขนาดโต๊ะหมุนมีสองแบบ 160 mm 270 mm

Last Update : 09:12:10 18/12/2023

Carbide insert

Brand : KHAN

Model : Work Gripper Carbide insert : PC127-10SC PC127-4SC PC130-4SC PC145-5SC PC132-4SC PC070-12SC PC070-4SC PC130-2SC-S PC127-4SC-S

ฟันจิกชิ้นงานสำหรับงานหล่อ Carbide insert PC127-4SC-S PC127-2SC-S PC130-2SC-S PC132-2SC-S PC070-12SC PC070-4SC PC046-4SC PC050-4SC Carbide Insert : PC-127-4SC-S : SOUL

Model : Work Gripper Carbide insert : PC127-10SC PC127-4SC PC130-4SC PC145-5SC PC132-4SC PC070-12SC PC070-4SC PC130-2SC-S PC127-4SC-S

ฟันจิกชิ้นงานสำหรับงานหล่อ Carbide insert PC127-4SC-S PC127-2SC-S PC130-2SC-S PC132-2SC-S PC070-12SC PC070-4SC PC046-4SC PC050-4SC Carbide Insert : PC-127-4SC-S : SOUL

Last Update : 10:12:51 01/11/2023