Machine Tool Gauges

TAC Rockford offers the world's largest variety of gauges and preventive maintenance tools for the machine tool industry designed to detect problems in machining centers before they become serious. Products include the ForceCheck gage for measuring tool holder clamping force, spindle run-out test bars, tool changer alignment tools, collet and chuck force measurement tools, and spindle and tool holder dimensional gauges.

Units are available for CAT/DIN/BT tapers in basic contact gauges, dial indicator gauges, as well as air gauges. For HSK, we offer dial indicator, electronic, and air gauges.

ForceCheck gauges from TAC Rockford are for preventive maintenance on machine tools, such as the power draw-bar spindle interface, chucks/turning-centers, and other machining applications. Since some spindles and turning-centers are standard, and other force measuring requirements might be unique, we offer an expansive product line of gauges to suit the needs for anyone in the machine tool industry.

Products by Type

Machine Tool Gauges Machine Tool Gauges

Why Check Drawbar Force?

Is your power drawbar working correctly?

Improve tool life and part finish

Correct tool holding force ensures that the spindle-tool holder interface is as rigid as possible. A rigid interface will improve tool life by reducing chatter and excess wear, and in turn improve workpiece finish.

Protect your spindles and ensure machining accuracy

Insufficient tool holding force can quickly wear or damage the critical spindle taper resulting in loss of machine accuracy and an expensive repair bill.

For the HSK taper, wear and damage on the spindle taper are even more detrimental. The HSK taper relies on an interference fit between the spindle and tool holder tapers, meaning drawbar force must be sufficient for the tool holder to properly seat. Because the HSK interface seats both on the tool holder taper and flange, dimensional tolerances are extremely tight. For HSK forms E and F, correct clamping force is crucial because there are not drive keys or dogs to transmit torque–the system relies entirely on the power drawbar's holding force.

Predict problems with the spindle's Belleville / disk spring stack

Machining centers with automatic tool clamping systems typically use Belleville/disk spring stack to hold a tool in the spindle, with a hydraulic cylinder used to overcome the spring force to unclamp the tool.

High RPM is often an important design criterion for a spindle, meaning the use of small diameter bearings makes sense from an engineering standpoint. Small bearings necessitate the use of small diameter springs to fit into the spindle arbor. Small-diameter springs lead to highly stressed springs for tool clamping, and even more so during tool unclamp.

A typical drawbar spring stack is designed to last approximately 1 million cycles. This may sound like a big number, but tool changes add up quickly. An example: a process with 3 to 4 tool changes per minute (many do much more), with 2,000 operating hours per year (one shift), means between 360,000 and 480,000 cycles are made per year. In this scenario, the springs have reached the end of the design life cycle and should be replaced after two years. We have found some processes that reach 1 million cycles after 6 months–with the complaint that the "springs break all the time."

Springs will not break all at once. Initially only one spring might break without significant impact on tool holding force. However, soon others will break since they have to do the work of the broken spring (or springs) as well. The rest of the springs will be overloaded and break or take a permanent set.

This failure process can be detected with a clamping force measuring device and action be taken before the clamping system fails completely.

Check for the role that friction plays in the clamping system and for proper lubrication

Some drawbar designs use a mechanical force intensification mechanism to increase tool holding force. When force intensification is used, friction is a factor to be watched. It is difficult to quantify friction without measurement. Machine builders typically provide a tool holding force specification for properly lubricated and adjusted clamping system.

Most power drawbar systems with HSK tapers use force intensification in the gripper design. The mechanical intensification of the force is typically between 3 and 9 times, making friction a major factor in the proper operation of the system.

For systems with manual HSK grippers such as those supplied by Mapal and Guehring, periodic verification of correct tool holding force is also of critical importance. Per manufacturer recommendation, tools should be clamped using a torque wrench to ensure correct force. However, if the gripper is not properly lubricated, tool holding force will be much lower at the specified torque.

Operator safety

Eventually, the tool holding system of a machine will fail catastrophically if left unchecked. There will be lots of mysterious problems such as poor part finish and broken tools, and eventually leading to the tool flying out of the spindle and damaging the workpiece, machine, or worse–injuring the operator.

Standards compliance

- The ISO and DIN HSK standards have recommended minimum clamping forces. The ForceCheck gauge can verify that these are met.

- The "CAT" steep taper standard ASME B5.50 specifically recommends using a drawbar force gauge.

- ISO 9000 compliance requires that critical machine parameters be periodically checked.

Measuring bars, complete sets, and base sets for all HSK type spindles. Contact us for other wireless and carrying case options.

Measuring bars, complete sets, and base sets for Steep Taper (MAS 403-BT) JIS standard.

Measuring bars, complete sets, and base sets for Steep Taper (SK) DIN standard. Metric or inch retention knob / pull-stud threading available on each measuring bar.

Measuring bars, complete sets, and base sets for Steep Taper (SK) CAT-ANSI. Metric or inch retention knob / pull-stud threading available on each measuring bar.

Measuring bars, complete sets, and base units for measuring drawbar force on a Steep Taper (SK) ISO standard spindle.

Measuring bars, complete sets, and base units for measuring drawbar force on Coromant Capto spindles (Polygonal Shank Taper - PSK).

Measuring bars, complete sets, and base units for measuring drawbar force on a Kenna

Tool Changer Alignment Gauges

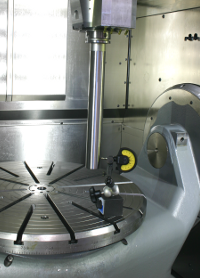

Tool changer alignment gauges are used to check automatic tool changer positioning between the gripper arm, magazine, tool holder, and the spindle.

Improper alignment results in abnormal wear on spindle and tool holder tapers, faulty clamping, dropped tools, and decreased machine repeatability – resulting in reduced productivity and expensive machine damage.

Tool changer alignment gauges from TAC Rockford make correct alignment between the spindle and automatic tool changer easy.

Sets include taper and flange, axial and radial alignment pins, and a padded carrying case.

Details Details  PDF (440.K00) PDF (440.K00)

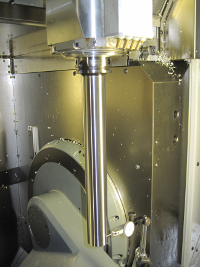

Runout Test Arbors

Spindle runout arbors offer a quick and easy way to verify that a machine spindle is running true after a crash, after a machine has been moved, or periodically as a performance check. Arbors are available for all major machine tapers, including CAT/DIN/BT Steep Taper, HSK, Capto, Morse, and others.

Available for HSK-A/C/E 32, 40, 50, 65, 80, 100, 125, 160 and HSK-F 40, 50, 63, 80, 100, 125, 160

Details Details  PDF (465.100) PDF (465.100)

Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

Details Details  PDF (465.800) PDF (465.800)

|

| Steep Taper (BT) 30 |

300 |

40 |

|

|

M12 |

|

|

465.730.000.000

|

| Steep Taper (BT) 40 |

300 |

40 |

|

|

M16 |

|

|

465.740.000.000

|

| Steep Taper (BT) 50 |

300 |

40 |

|

|

|

|

|

465.750.000.000

|

| Steep Taper (DIN) 30 |

300 |

32 |

|

|

M12 |

|

|

465.830.000.000

|

| Steep Taper (DIN) 40 |

300 |

40 |

|

|

M16 |

|

|

465.840.000.000

|

| Steep Taper (DIN) 45 |

300 |

50 |

|

|

M20 |

|

|

465.845.000.000

|

| Steep Taper (DIN) 50 |

300 |

50 |

|

|

M24 |

|

|

465.850.000.000

|

| Steep Taper (DIN) 60 |

400 |

50 |

|

|

M30 |

|

Drawbar position gauges are used to adjust and set drawbar stroke position on HSK machine tool spindles. The gauges allow the clamping angle to be adjusted to the high and low limits, allowing the stroke position to be set.

Details Details  PDF (470.210) PDF (470.210)

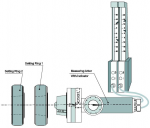

Steep Taper (SK) Tool Holder Taper Dimensional Gauges

These gauges are designed to test the quality and precision of the tool holder taper of steep taper DIN, CAT/ANSI, MAS 403-BT, or ISO standards. Specific testing standards for other tapers may also be available.

While the gauges check the precise measurement of the tool holder taper, it is recommended to check the milling spindle-interface dimensions as well. For some kits, adapters can be included as a customized kit for checking both the taper and spindle dimensions. Learn more about milling spindle dimensional checking gauges.

Available for Steep Taper CAT/ANSI/DIN/BT/ISO 10, 15, 20, 25, 30, 35 40, 45, 50, 55, 60, 65

Details Details  PDF (430.110) PDF (430.110)

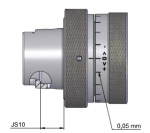

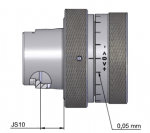

HSK Tool Holder Dimensional Gauges

Using the calibrated master, the distance of the 30 degree clamping slope relative to l 2 is preset using the dial indicator holder. The tool taper to be measured is placed in the centering piece, allowing the variation of the taper to be measured.

Details Details  PDF (410.230) PDF (410.230)

|

| HSK-A 25 |

HSK 32 |

7.21 |

15 |

|

|

|

|

410.230.125.000

|

| HSK-A 32 |

HSK 40 |

8.92 |

19 |

|

|

|

|

410.230.132.000

|

| HSK-A 40 |

HSK 50 |

11.42 |

23 |

|

|

|

|

410.230.140.000

|

| HSK-A 50 |

HSK 63 |

14.13 |

29 |

|

|

|

|

410.230.150.000

|

| HSK-A 63 |

HSK 80 |

18.13 |

37 |

|

|

|

|

410.230.163.000

|

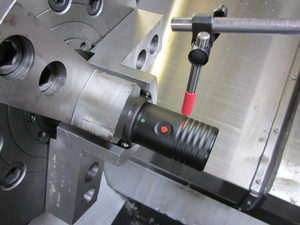

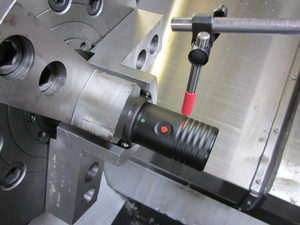

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers to improve the repeatability of a manufacturing process by checking actual holding force under dynamic (rotating) conditions, as well as perform critical preventative maintenance checks. Contact us for other clamping diameters and extension rings, as well as 4+ jaw chucks.

Series 492.026 ring gauges are for lathe spindle face. Series 492.028 plug gauges are for chuck back side mounting face. Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges also available. Cases are not included. Contact us for high quality gauge crib and travel case options.

ForceCheck Turning-Center Chuck Force Gauges

Turning-center force sensors are designed to measure the holding force of clamp jaws on chucks. This allows manufacturers to make critical adjustments, and improve repeatability and workpiece quality. The wireless version of the chuck force gauge is able to measure RPM along with force.

For more advanced features, such as graphing and testing multiple machines as part of a preventive maintenance plan, a tablet that universally connects to any ForceCheck sensor is also available. Contact us for more specifications and details on advanced machine force measuring.

Designed to quickly check the holding force on a chuck or turning-center. The wired chuck force gauge can be customized for any diameter.

Details Details  PDF (495.205) PDF (495.205)

Runout Test Bars for Lathes, Chucks, and Turning Centers

TAC Rockford manufacturers runout arbors for chucks as a special order item. Please contact us for further information.

Details Details  PDF (490.510) PDF (490.510)

Lathe Spindle Face Ring and Taper Plug Gauges

For measuring the dimensions of lathes and chucks

Series 492.026 ring gauges are for lathe spindle face.

Series 492.028 plug gauges are for chuck back side mounting face.

Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges also available.

Cases are not included. Contact us for high quality gauge crib and travel case options.

|

| DIN55026-3, DIN55027-3, A1-3, A2-3, B1-3, B2-3 |

|

|

|

3 |

53.983 |

53.975 |

Ring |

492.026.003.000

|

| DIN55026-4, DIN55027-4, A1-4, A2-4, B1-4, B2-4 |

|

|

|

4 |

63.521 |

63.513 |

Ring |

492.026.004.000

|

| DIN55026-5, DIN55027-5, A1-5, A2-5, B1-5, B2-5 |

|

|

|

5 |

82.573 |

82.563 |

Ring |

492.026.005.000

|

| DIN55026-6, DIN55027-6, A1-6, A2-6, B1-6, B2-6 |

|

|

|

6 |

106.385 |

106.375 |

Ring |

492.026.006.000

|

| DIN55026-8, DIN55027-8, A1-8, A2-8, B1-8, B2-8 |

|

|

|

8 |

139.731 |

139.719 |

Ring |

492.026.008.000

|

| DIN55026-11, DIN55027-11, A1-11, A2-11, B1-11, B2-11 |

|

|

|

11 |

196.883 |

196.869 |

Ring |

492.026.011.000

|

| DIN55028-3, DIN55029-3 |

|

|

|

3 |

|

|

Plug |

492.028.003.000

|

| DIN55028-4, DIN55029-4 |

|

|

|

4 |

|

|

Plug |

492.028.004.000

|

| DIN55028-5, DIN55029-5 |

|

|

|

5 |

|

|

Plug |

492.028.005.000

|

| DIN55028-6, DIN55029-6 |

|

|

|

6 |

|

|

Plug |

492.028.006.000

|

| DIN55028-8, DIN55029-8 |

|

|

|

8 |

|

|

Plug |

492.028.008.000

|

| DIN55028-11, DIN55029-11 |

|

|

|

11 |

|

|

Plug |

492.028.011.000

|

TAC Rockford gauges are used for inspection of steep taper spindle tapers per CAT, ISO, JIS, DIN, etc. Available for Steep Taper 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60,...

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case:...

The four transducers mounted in the measuring ring are used for differential measurement of gauge dimensions d2 and d3. Deviations from the calibrated taper plug gauge are...

Both measuring gauges are set to zero with the calibrated taper plug gauge. When an HSK tool holder is inserted in the ring gauges, deviations in diameters d2 or d3 are shown...

Available for Steep Taper CAT/ANSI/DIN/BT/ISO 10, 15, 20, 25, 30, 35 40, 45, 50, 55, 60, 65

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should...

TAC Rockford Morse spindle taper gauges are for inspection of Morse spindle tapers. Gauges made from a hardened gauge steel, and include a padded carrying case and certificate....

Non-contact measuring with nozzles results in high accuracy and consistency of measuring results. The measuring range can be increased with the built-in dial indicator. This...

Download PDF for instruction manual.

Products by Type

Dimensional Measuring Dimensional Measuring

About

The collet force gauge allows tool holder and workholding collet holding force to be quickly and easily measured. Because it is problematic to measure, this critical holding force is typically not checked, even though it is an important role in manufacturing repeatability. The collet force gauge allows tool holder and workholding collet holding force to be quickly and easily measured. Because it is problematic to measure, this critical holding force is typically not checked, even though it is an important role in manufacturing repeatability.

Accurate, quick and simple measuring of the clamping force of hydraulic chucks.

Details Details  PDF (483.038) PDF (483.038)

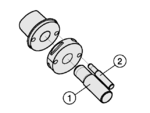

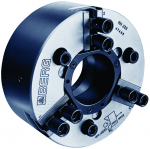

BERG Pallet Clamping Force Gauges

Includes measuring case, display unit, measuring cartridge, test certificate, and clamping head specific pull studs

ApplicationThe BERG clamping force measuring system for clamping heads is intended to measure the force of individual clamping heads. The transfer of data via the series interface makes it possible to check and document all clamping positions.

Design featuresThe measuring system consists of a sturdy, handy display unit, the measuring cartridge with integrated force sensor as well as the clamping bolts required for the respective clamping head. The measuring data can be transferred to a Windows PC via a serial interface of the hand-held display unit. The measuring system comes in a sturdy plastic measuring case, accommodating the display unit, measuring cartridge and clamping head specific pull studs.

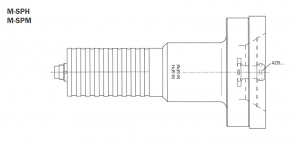

BERG Spanntechnik series SPH clamping heads are primarily used for horizontal pallet clamping. The heads form the basis of a highly rigid, high precision repeatable workholding...

Clamping heads of the series SPH-V are principally used in machining centers for vertical pallet clamping. The series SPH-V is based on the basic principle of the SPH. The...

SPM-HV series pallet clamping heads are used for pallet clamping on single or double axis indexing tables. With the clamping heads and matching tapered rings, maximum workpiece...

Custom-Built Machine Gauges

We can build custom gauges for any machine or machine designed specifically for any application and requirements – even gauges not designed or built by anyone else! Interface options include multi-language support, multiple measuring capabilities, and any communication method.

We can build custom gauges for any machine or machine designed specifically for any application and requirements – even gauges not designed or built by anyone else! Interface options include multi-language support, multiple measuring capabilities, and any communication method.

Application examples for preventative maintenance:• Workpiece holding and clamping systems: Is your machine using proper force and alignment consistently? Could wear or friction be on internal components? A gauge can be designed to fit the constraints or model of a workholding machine or part with any unique specifications.

• Turning centers, spindles, and lathes: Alignment/centering, speed, force, and axial positioning are crucial measurements to test for repeatability, wear on internal or external components, and overall run-out of a machining system.

• CNC Machines: Many costly and destructive damages can occur if detrimental elements of CNC machines are not checked on a regular basis – chances are, we already have a gauge designed to inspect these elements. If your machine is unique by most standards, we can easily provide a solution.

• Actuators and positioning systems: Test for repeatability and accuracy under any system. Preventative maintenance gauges may also improve the threshold and operating conditions a machine system can work at, as well as test for issues before they occur and cause damage.

Examples of features and options:• Rotational and torque measuring (RPM) for spindles, lathes, and turning centers

• Axial positional measuring

• Custom functions or features for a display

• Data logging and wireless data transmission

• Calibration and conversion to any measuring units or specifications

• Support for multiple languages

• USB, Serial, PC, and Network interfaces

• Tool holder, drawbar, and spindle designs with specific dimensions, unique standards, and integration with even unsupported components

• Gauges built with special materials for different environments

• Machine tool integrated clamping force reading

• On-demand measuring and preventive maintenance systems

Available for HSK-A/C/E 32, 40, 50, 65, 80, 100, 125, 160 and HSK-F 40, 50, 63, 80, 100, 125, 160

Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

Calibrated with a gauge master, the taper gauge checks large taper diameter, small taper diameter, straightness of the taper, relationship of the flange to the taper, and...

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers...

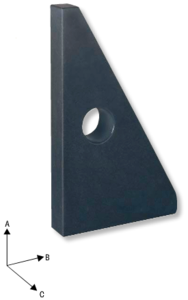

aster Granite Setup Squares (90 degrees)

Made to DIN 875 / DIN 876 standard

Granite block with two diamond-lapped measuring faces. Made in Germany to DIN 875 / 876 standard.

• Manufactured per DIN875/876

• 2 measuring faces, diamond lapped, corrosion-free and acid resistant.

• Ground outer faces

• Sizes larger than 500x300mm have threaded inserts for eyebolts

• Include certificate

• Made in Germany

Standard squares are 00 accuracy class. Contact us for higher accuracy class 000 squares. Custom sizes also available.

Storage cases not included. Contact us for available types.

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines....

The dial gauge indicates the distance between spindle axis and workpiece edge. As soon as the gauge shows zero, the spindle axis is exactly on the workpiece edge on the first...

Calibrated with a gauge master, the taper gauge checks large taper diameter, small taper diameter, straightness of the taper, relationship of the flange to the taper, and...

Available for 30, 35, 40, 45, 50 taper tool holders

Available for 32, 40, 50, 63

Available for 32, 40, 50, 63, 80, 100

Available for HSK-A 32, 40, 50, 63, 80, 100

To check the extremely small tolerances required by the DIN and ISO

standards for HSK tool holders.

The High Precision Gauge Masters are made of a proprietary stabilized gauge material and are coated to resist corrosion. Actual dimensions are laser marked on the master....

Precision Measuring Cylinders

90 degree measuring cylinder with handle

Hardened special steel. Machined base and jacket surface.

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping...

Gauging kit for Steep Taper, CAT/ANSI, ISO, BT spindles with pneumatic measuring system. The Multifunctional Measuring and Control Device is designed for high precision and...

Gauging kit for Steep Taper, CAT/ANSI, ISO, BT tool holder tapers with pneumatic column. The Multifunctional Measuring and Control Device is designed for high precision and...

Custom-cut foam heavy-duty gauge cases, made special to order for TAC Rockford gauge sets. Ideal for heavy gauges, test bars, test rings, and machine measuring cylinders.<br...< p="">

|

|

|